Industrial Machinery Components [2025 Guide]

Industrial Machinery Components – Industrial environments use a wide variety of machinery, each serving a specific function.

Because most machinery in the industry is designed for a specific purpose, manufacturers must build these machines with high-quality components to ensure they perform reliably and efficiently.

Also, it’s crucial to be familiar with the many components and their applications, as their utilization varies by industry.

What is considered industrial machinery?

The term industrial machinery encompasses any machine utilized in a commercial or industrial setting. Oil fields and building or construction equipment are examples of industrial machinery.

Industrial machines are complex systems that enhance productivity and ensure precision by combining various components, each with a crucial role. To optimize performance, prolong equipment lifespan, and ensure safety, engineers, technicians, and stakeholders must thoroughly understand these components.

Simply put, industrial machinery components are the individual parts and assemblies that make up industrial equipment. Designed to perform specific functions, these components collectively drive the operation of machinery in industries such as manufacturing, oil and gas, agriculture, mining, and transportation.

Industry standards and guidelines are provided by the International Organization for Standardization (ISO) (which provides standards for machinery components and safety) and the American Society of Mechanical Engineers (ASME) which provides resources on component design and maintenance practices).

Industrial Machinery Components

The components of a machine can be broken down into four categories, namely:

- Control components.

- Electrical components.

- Movement-regulating components.

- Structural components.

- Optical components (include telescopes, lenses, and mirrors).

Below is the comprehensive and detailed list of industrial machinery components:

- Actuators

- Axles

- Beams and Struts

- Bearings

- Belt and cable drives

- Brakes and Clutches

- Bushings

- Buttons

- Cam and follower systems

- Chain

- Compressors

- Computer controllers

- Couplings

- Electric motor

- Engine

- Fasteners

- Flywheel

- Fuel pump

- Gear trains

- High-pressure nozzles

- Hydraulics

- Indicators

- Keys and Cotter pin

- Lamps

- Linkages

- Lubricants

- Machine guard

- Meters

- Oil cooler

- Pulleys

- Pumps

- Screws

- Seals

- Seat

- Sensors

- Shafts

- Splines

- Sprocket

- Switches

- Valves

Key Categories of Industrial Machinery Components

- Mechanical Components:

- Gears and Gear Systems: Used for transmitting power between machine parts, altering speed, and torque.

- Bearings: Facilitate smooth rotation or linear motion and reduce friction.

- Couplings: Connect two shafts to transfer power, allowing for misalignment and absorbing shock loads.

- Fasteners: Includes bolts, screws, and nuts that hold various components together.

- Springs: Store and release energy to maintain force and absorb shock.

- Hydraulic and Pneumatic Components:

- Pumps: Move fluids in hydraulic systems or compress gases in pneumatic systems.

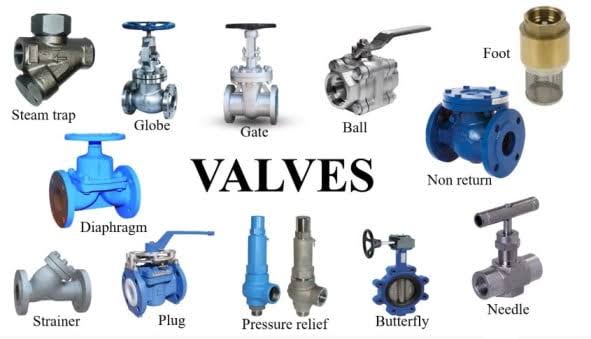

- Valves: Control fluid flow, pressure, and direction.

- Cylinders: Convert fluid power into linear mechanical force.

- Hoses and Fittings: Transport fluids and connect hydraulic components.

- Electrical Components:

- Motors: Convert electrical energy into mechanical motion.

- Sensors: Monitor conditions like temperature, pressure, or vibration.

- Controllers: Automate processes and manage machine operations.

- Wiring and Connectors: Provide electrical connections and transmit power and signals.

- Structural Components:

- Frames and Chassis: Provide structural integrity and support.

- Enclosures: Protect internal components from environmental factors.

- Lubrication Systems:

- Ensure minimal friction and wear between moving parts, increasing efficiency and reducing downtime.

- Specialized Components:

- Components like turbines, compressors, and advanced sensors tailored to specific industries (e.g., oil and gas, aerospace).

Detail Descriptions of Some Industrial Machinery Components:

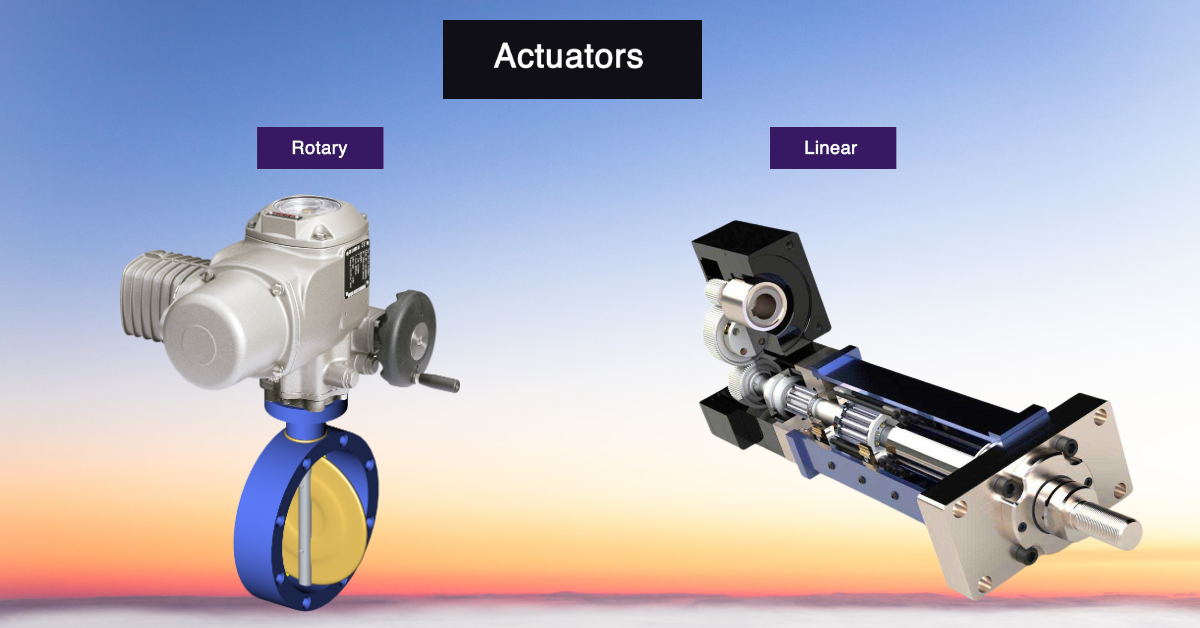

1. Actuators

One definition of an actuator is “a machine part that moves and controls some mechanism or system, like by opening a valve.” In layman’s words, it’s a “mover.”

Also, the types of actuators include; Soft actuators, Hydraulic, Pneumatic, Electric (including Electromechanical actuators (EMA), Electrohydraulic actuators, Linear motors), Thermal or magnetic, and Mechanical.

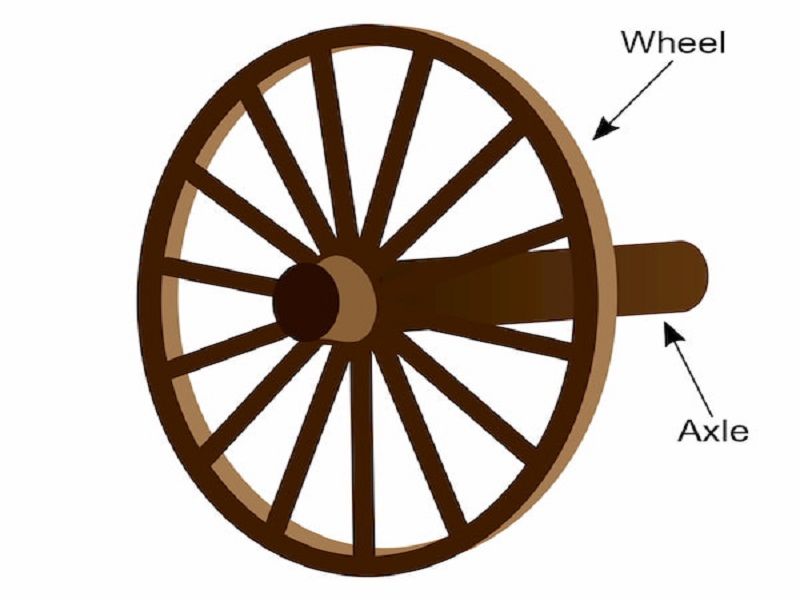

2. Axles

An axle, or axletree, serves as the central shaft enabling a wheel or gear to rotate. In vehicles with wheels, the axle either rigidly attaches to the vehicle and rotates along with the wheels, or it remains stationary while the wheels rotate around it.

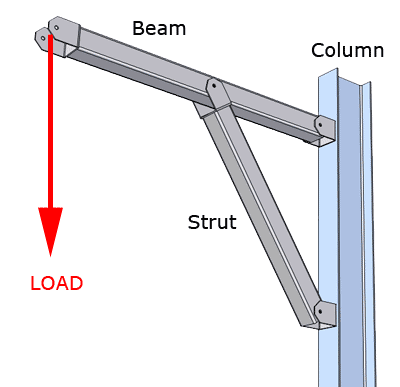

3. Beams and Struts

Beams are structural elements that predominantly resist loads perpendicular to the beam’s axis. When deflected, it bends rather than breaks.

Struts are most effective in stopping longitudinal compression, though they can also be used in tension.

4. Bearings

A bearing is a component that decreases friction and provides smooth relative motion.

At least six different types of bearings are in widespread use, each with its unique mode of operation; these include Plain bearings, Rolling-element bearings (Ball bearing and Roller bearing), Jewel bearings, Fluid bearings, Magnetic bearings, and Flexure bearings.

5. Belt and Cable Drives

Belts are loops of flexible material that are mechanically linked to two or more parallel spinning shafts. Belts have multiple applications, including creating movement, efficiently transmitting electricity, and detecting and analyzing relative motion.

Cables are used in a cable drive (also known as cable transmission) to transmit rotational motion from one shaft to another.

But flat belt drives, which use smooth wheels and a belt, are just one cable drive that gives way to electric components in modern machinery. So, one of the many modern applications for cable drives is in block and tackle systems.

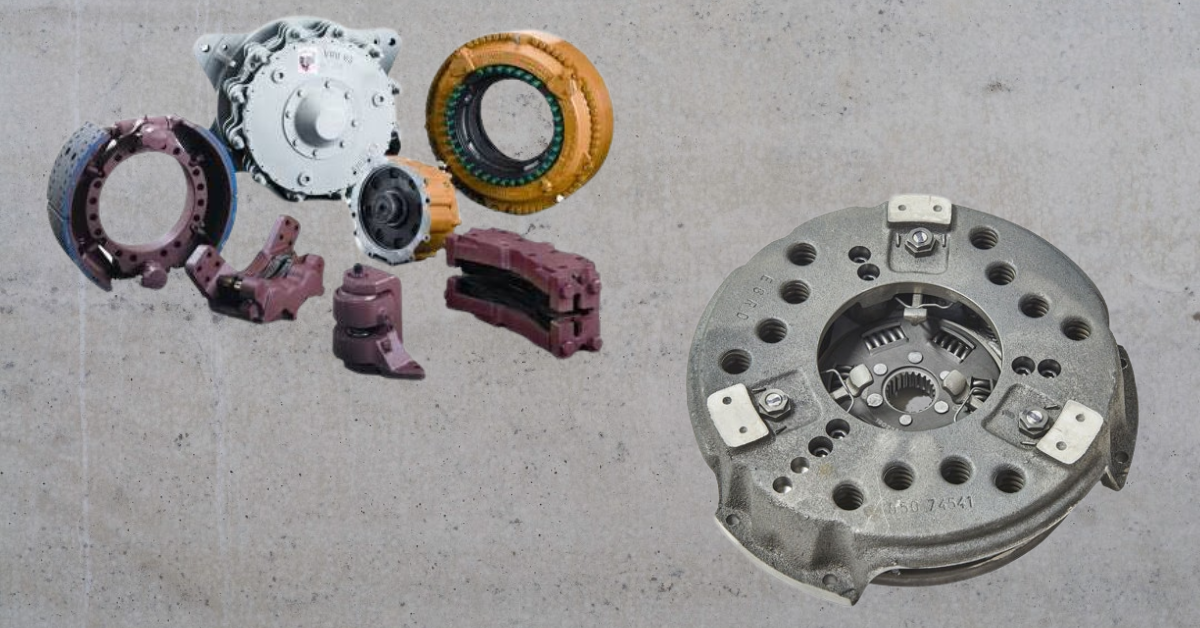

6. Brakes and Clutches

A brake is a mechanical mechanism that slows down a moving system by soaking up the kinetic energy it produces.

Also, its primary function is to reduce or halt the rotation of a wheel, axle, or vehicle by creating frictional resistance to motion. Types of brakes include frictional, pumping, and electromagnetic.

But a clutch engages and disengages power transfer, often from a drive shaft to a driven shaft. Clutches are used to couple and disengage two spinning shafts in their most basic form.

7. Bushings

A bushing is an easily replaceable cylindrical lining or sleeve used in machinery to lessen the impact of friction on moving parts, minimize the size of a hole, etc.

8. Buttons

A button is a simple switch to activate or deactivate an action or function in a machine or system.

9. Cam and Follower Systems

Mechanical linkages often include rotating or sliding components known as cams, which convert rotary motion into linear motion.

But cam followers, sometimes called track followers, are a type of roller or needle bearing specifically made to follow the contours of cam lobes. Types of cam followers include Anti-friction elements, Shape, Stud (Drives and Eccentricity), and Yoke.

10. Chain

Like a rope, a chain is a series of interconnected parts called links that stretches and curves under compression but straightens and become more rigid under tension.

Also, chains include ball chains, calibrated chains, flat chains, ladder chains, long link chains, O-ring chains, Roller chains, self-lubricating chains, silent chains, stud link chains, and short link chains.

11. Compressors

Compressors are mechanical tools for raising air pressure and other gases amenable to compression, and there are two basic types of air compressors: Positive displacement and Dynamic.

12. Computer Controllers

Computer controller refers to an industrial computer customized for machines, robotic devices, and other production processes that necessitate high dependability, simple programming, and rapid problem identification.

13. Couplings

A coupling is a tool that joins two shafts’ ends to transfer mechanical energy. Also, couplings unite two pieces of rotating equipment to allow for misalignment, end movement, or both.

14. Electric motor

An electric motor is a type of electrical equipment that can transform electrical energy into mechanical energy. Also, torque is applied to the motor shaft when an electric current flows through a wire winding and interacts with the motor’s magnetic field.

15. Engine

A machine that uses one or more energy sources to generate mechanical energy is called an engine or motor.

16. Fasteners

A fastener, or fastening, is a piece of hardware used to attach or link two or multiple objects together mechanically.

In most cases, fasteners affix two objects together that are not intended to last permanently and can be disassembled without causing any damage to either of the original parts.

17. Flywheel

A flywheel is a mechanical tool that stores rotational energy, a form of kinetic energy that is proportional to the product of the moment of inertia and the square of the rotating speed, by using the conservation of angular momentum.

18. Fuel pump

A fuel pump is a mechanical or electronic pump that extracts fuel from a tank to feed a carburetor or fuel injection system with fuel.

19. Gear trains

A gear train forms a mechanical system by mounting gears on a frame, ensuring their teeth engage effectively. To achieve seamless rotation transmission from one gear to the next, engineers design the gear teeth so that the pitch circles of engaging gears roll over each other without slipping.

20. High-pressure nozzles

Processes like spraying coolant on a tool when machining it and washing and painting huge objects like tanks are made simple and effective using high-pressure nozzles. But understanding the product details is essential before making a purchase decision.

21. Hydraulics

Hydraulics is a branch of engineering that uses pressurized liquids to accomplish tasks, including power generation, control, and transmission, in the context of fluid power applications.

So, in other words, one mechanical function that uses liquid pressure is known as hydraulics.

22. Indicators

The industrial machine indicator is suitable for machine tools, mechanical equipment, etc.

23. Keys and Cotter pin

To link a rotating machine part to a shaft, mechanical engineers need a “key.” Because the key locks the two pieces in place, preventing them from turning about one another, which could allow torque to be transmitted.

But a cotter pin, often called a cotter key, is a metal fastener with two tines bent during installation, much like a rivet or staple. Also, there is a wide variety of cotter pins; however, most are thick wires with a half-circle cross section.

24. Lamps

An industrial machine lamp is essential for visibility when working late at night or in a dimly lit workshop.

25. Linkages

Mechanical linkages are networks of interconnected parts used to control motion and force.

26. Lubricants

A lubricant is a chemical agent used to lessen the heat produced by moving surfaces by decreasing the friction between them. But it could also be responsible for force transmission, particle transportation, and surface heating and cooling.

27. Machine guard

Machine guarding is a safety element installed on or near industrial machines and other technical tools and consists of a shield or device covering potentially dangerous sections of the machine to keep workers safe.

28. Meters

Industrial machine meters have functions such as an hour meter, fuel gauge, water temperature gauge etc. Sometimes, meters also determine the condition/status of the machine.

29. Oil cooler

An oil cooler is a tool that cools the engine oil.

30. Pulleys

A pulley is a wheel attached to a shaft or axle that facilitates the transfer of power or energy between the shaft and the cable or belt.

31. Pumps

A pump is another type of industrial machinery component that is rarely analyzed. But it has various applications in the manufacturing process and is utilized in virtually every industry to transport fluids and gases through a system.

32. Screws

Both the screw and the bolt are examples of male thread fasteners, which are metal and have a helical ridge.

33. Seals

A seal is a mechanical material that helps attach systems and mechanisms by preventing leakage, containing pressure, or keeping out contamination.

In addition, sealants rely on adhesion, and gaskets rely on compression to create an airtight seal.

34. Seat

An industrial machinery seat reduces the operator’s discomfort and features height adjustment, suspension, integrated controls, and more.

35. Sensors

A sensor in industrial machinery is a device that can detect and measure a physical effect and feed that data back into the control system.

A sensor is a piece of hardware that monitors its surroundings and relays that data to another piece of equipment, most often a computer system. In every case, sensors are integrated into a larger system of electronic devices.

36. Shafts

A drive shaft, driveshaft, driving shaft, tail shaft, propeller shaft, or Cardan shaft typically transmits mechanical power, torque, and rotation by connecting drivetrain components that cannot be directly connected due to distance or the need for relative movement between them.

37. Splines

Splines are ridges or teeth on a drive shaft that can transfer torque to a mating piece by fitting into corresponding grooves in that piece while keeping the two in proper angular alignment.

38. Sprocket

Sprockets, sprocket wheels, or chain wheels feature profiled wheels with teeth that mesh with a chain, track, or other perforated or indented material.

39. Switch Box

It is a series of switches that pick and determine the various aspects of the machine’s work settings and status. Furthermore, it’s a container for on/off switches for various purposes.

40. Valves

A valve is a device or an object that opens, closes, or partially obstructs passageways to regulate, control, or direct the flow of a fluid (liquids, gases, slurries, or fluidized solids).

Retailers and Dealers of Industrial Machinery Components in the United States

Before shopping for industrial machinery components, you should consider what you need, what you want, your budget, and how often you’ll need replacement components.

Most importantly, if you’re looking for a certain component, you should shop at internet stores and local dealerships.

Here are a few component manufacturers and suppliers:

-

- SKF Bearings: Specializes in bearings and lubrication systems.

- Parker Hannifin: Leader in motion and control technologies, including hydraulic and pneumatic components.

- Siemens: Provides industrial motors, sensors, and controllers.

Maintenance of Industrial Machinery Components

Here are some common types of maintenance of industrial machinery components:

Corrective maintenance

Corrective maintenance is done quickly after discovering a fault in an industrial machinery component. The purpose is to get the equipment to be functional again in a timely manner.

Preventive maintenance

Preventive maintenance is scheduled by technicians based on pre-established maintenance activities.

To carry out this kind of maintenance system, teams have to consider the history of the system failures.

Businesses commonly use innovative tools like computer-aided maintenance management systems (CMMS) to carry out preventive maintenance effectively.

Predictive maintenance

The purpose of predictive maintenance is to find out when an equipment fault is going to take place and then stop that failure by carrying out maintenance simply before it takes place.

A good predictive maintenance plan requires the ability to track the equipment’s condition. Experts utilise tools like vibration analysis, oil and fluid analysis, noise analysis and thermography.

Final Thoughts

The term “components” describes all the parts forming a piece of industrial machinery.

Also, the post-shock resistance of any industrial machinery component determines the component’s stability and efficiency. In other words, using shock-proof components can lessen the likelihood of malfunctions and repairs during use.

Shock-resistant components can be hard to come by, but with some research, you can find them.

Therefore, the key is to zero in on the perfect solution for your needs. Possessing a trustworthy contractor who can conduct these evaluations on your behalf is also beneficial.

Related: Trade Schools for Mechanics

We hope you find this information helpful. Please use any of the share buttons below to share this information.

Feel free to drop any questions or contributions regarding this article in the comment section below.